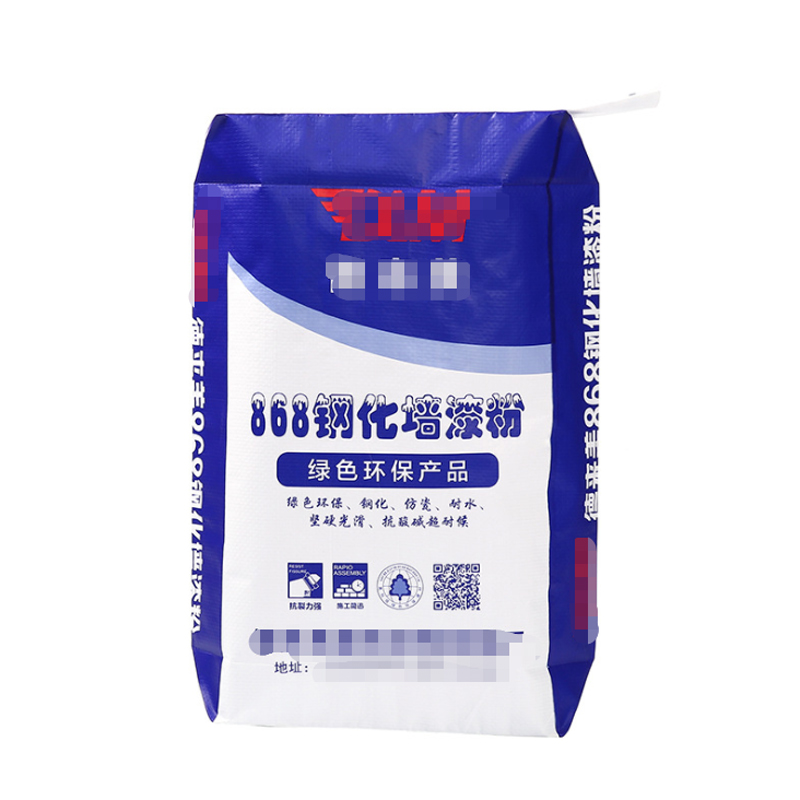

Factory Price For Valve Bag – PP Woven Block Bottom Putty Powder Valve Bag 20kg – Shengyuan

Product Introduction

Putty powder is a kind of building decoration materials, mainly composed of talc powder and glue. It is a base material used for wall repair and leveling. It can lay a better foundation for the decoration process.

Usually, putty powder is packaged with valve bag, which is generally divided into two kinds, paper and woven materials. As the putty powder is easily affected by moisture, plastic materials are generally added to the packaging bag to prevent moisture. For example, a layer of plastic film will be added to the paper valve bag. The woven valve bag itself is made of plastic, which will also achieve the effect of waterproof and moisture.

PP woven block bottom valve bag 20kg, made of coated polypropylene fabric, without adhesive. Compared with other industrial packaging, block bottom valve bag is the strongest packaging bag. Polypropylene fabric uses stretch tape to make the block bottom bag resistant to drop, compression and bending. The block bottom bag can resist small nails and hooks, making it more advantageous than other industrial bags.

Scope of use:

PP woven bag 20kg is widely used for powder and granular industrial packaging in cement, calcium, fine chemical, putty powder and other industries.

Advantage:

1. Design of outer valve port and inner valve port suitable for filling

2. Moisture proof, dust-proof and water prevention

3. Three dimensional shape is convenient for shipping

4. Clear printing, not easy to color and blur

5. The loading capacity is 20-50kg

The following are the product size recommendations, and the data are for reference only:

1. Putty powder – 15kg – 38 * 38 * 10 cm

2. Putty powder – 20kg – 40 * 45 * 10 cm

Customization requirements:

1. Color printing within 4 colors

2. Perforation process

3. Embossing

4. Valve port selection (inner valve port and outer valve port)

5. Special size customization

About Product

Related PRODUCTS

-

stevenwin6363

-

Top