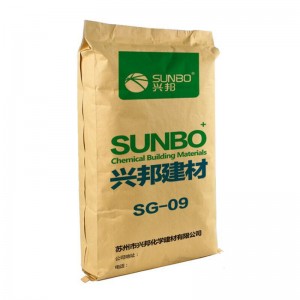

PP Laminated Kraft Paper Bag

Product Introduction

Paper plastic composite bag, also known as three in one composite paper bag, is a small bulk container, which mainly realizes unit transportation by manpower or forklift. It is easy to transport small bulk powder and granular materials. It has the characteristics of high strength, good waterproof, beautiful appearance and easy loading and unloading. It is a popular and practical ordinary packaging material at present.

Process Description:

Refined white kraft paper or yellow kraft paper is used outside and plastic woven cloth is used inside. The plastic particle PP is melted through high temperature and high pressure to compound kraft paper and plastic woven cloth together. An inner membrane bag can be added. The form of paper plastic composite bag is equivalent to sewing bottom and opening pocket. It has the advantages of good strength, waterproof and moisture-proof.

Details:

1. Length: 52-96cm

2. Width: 40-60cm

3. Material: the outermost layer can be white kraft paper or yellow kraft, according to the printing

4. Gram weight: the thickness of the most commonly used kraft paper is about 60-100g, and the woven material is about 60-80g

5. Printing color: 1-6 colors, which can be printed on one or both sides according to customer requirements

6. Bearing capacity: within 40kg

7. Quality inspection: meet SGS and ISO9001 production standards

Product advantages:

1. Inner weaving: polypropylene (PP) woven fabric laminated kraft paper bag is made by weaving polypropylene (PP) or high density polyethylene (HDPE) tape into the fabric, with high durability and puncture resistance. More protection, more confidence, better protection, better leak proof and wear-resistant function

2. Superior kraft paper: enhanced wear resistance and more three-dimensional loading

3. The bag mouth is neat: it adopts mechanized integrated cutting technology, high temperature hot cutting and no wire drawing

About Product

Related PRODUCTS

-

stevenwin6363

-

Top